In chemistry, hydrophobicity (from the Attic Greek hydro, meaning water, and phobos, meaning fear) is the physical property of a molecule (known as a hydrophobe) that is repelled from a mass of water.

hydrophobicity: noun; the property of being water-repellent; tending to repel and not absorb water / Synonyms for hydrophobic: aquaphobic, water repellent

Do scientists think water is wet? [8]

Water is not wet because wetness arises from the interaction between a liquid and a solid surface. In other words, wetness is a property that occurs when water or another liquid comes into contact with a solid object.

Hydrophobic molecules tend to be non-polar and, thus, prefer other neutral molecules and non-polar solvents. Hydrophobic molecules in water often cluster together, forming micelles. Water on hydrophobic surfaces will exhibit a high contact angle.

Examples of hydrophobic molecules include the alkanes, oils, fats, and greasy substances in general. Hydrophobic materials are used for oil removal from water, the management of oil spills, and chemical separation processes to remove non-polar from polar compounds.

Hydrophobic is often used interchangeably with lipophilic, "fat-loving." However, the two terms are not synonymous. While hydrophobic substances are usually lipophilic, there are exceptions—such as the silicones and fluorocarbons.[1]

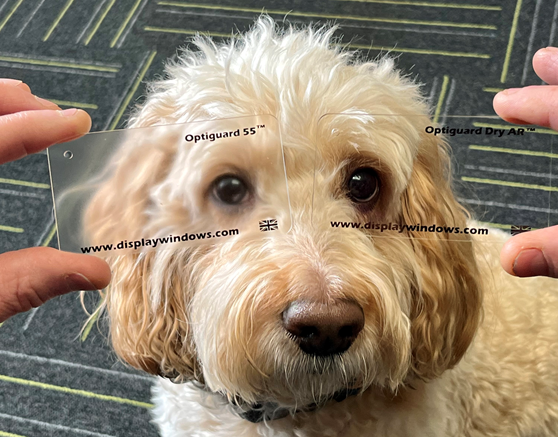

A superhydrophobic coating is a thin surface layer that repels water.

It is made from superhydrophobic (ultrahydrophobicity) materials. Droplets hitting this kind of coating can fully rebound.

Superhydrophobic surfaces, possessing a high water contact angle (> 150°) and low sliding angle (< 10°), have attracted considerable attention because of their high water repellency and attractive self-cleaning, anti-corrosion, anti-icing, and anti-fouling properties.[4]

Thin layers of a waterproof substance on the surface of hydrophilic materials. Hydrophobic coatings are often called water-repellent, which is incorrect, since the water molecules are attracted to the coatings, although extremely weakly, rather than repelled by them.

Hydrophobic coatings are produced in the form of monomolecular layers (adsorbed orientated layers one molecule thick) or lacquer films by treating a material with solutions, emulsions, or less frequently, vapors of hydrophobic agents, which are substances that interact weakly with water but attach themselves firmly to a surface. Substances used as hydrophobic agents include salts of fatty acids and such metals as copper, aluminum, and zirconium; cation-active surface-active agents; and low-and high-molecular-weight organosilicon and organic fluorine compounds.

Hydrophobic coatings protect various materials (metal, wood, plastics, leather, and fabric and nonfabric fibrous ma-terials) from the destructive action of water or wetting. They are used particularly extensively in machine building,construction, and textile production.[2]

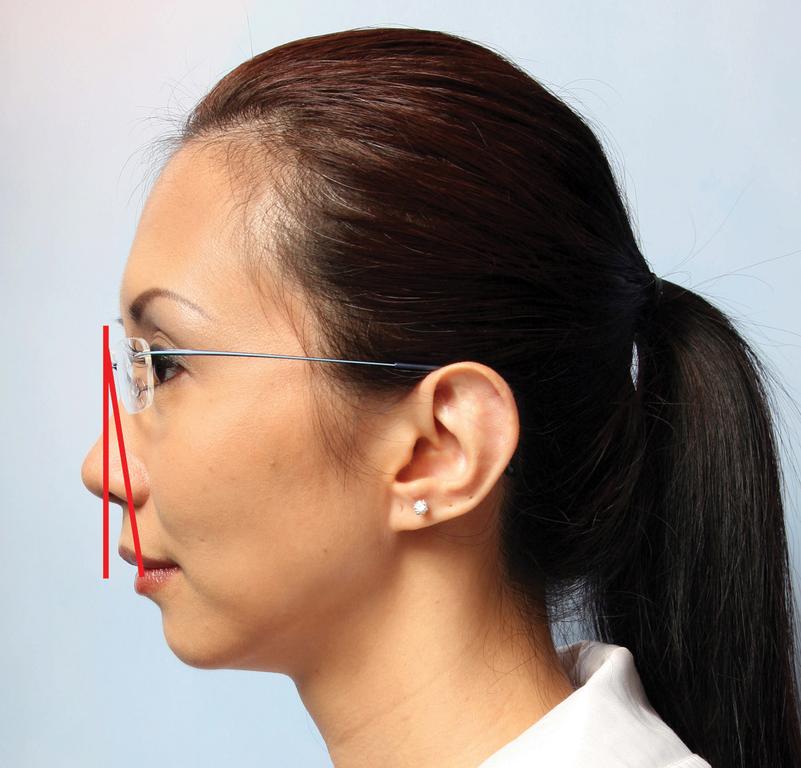

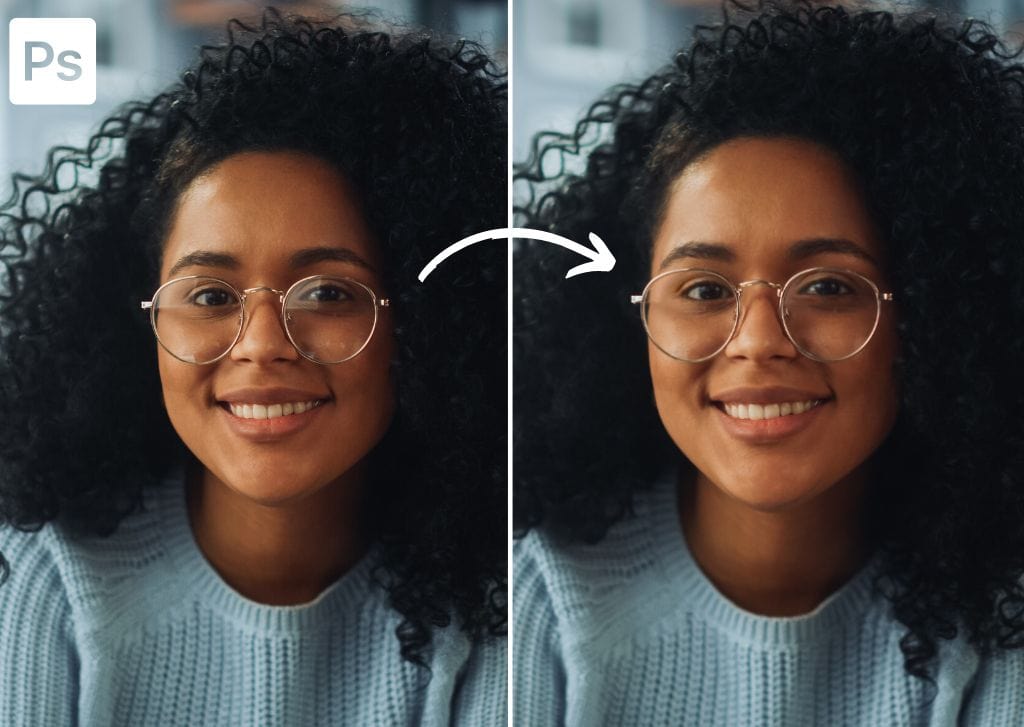

If you live in a cold climate, nothing is more frustrating than having your eyeglasses fog up when you come in from the cold. This also can be a safety issue, since it limits your ability to see until the fog clears. Lens fogging can be especially dangerous for police officers and other first responders to emergency situations. eResearch by Navid Ajamin -- spring 2012

At least one eyeglass lens coating company (Opticote) has created a permanent coating designed to eliminate this problem. The factory-applied coating — called Fog Free — eliminates the condensation of moisture on lenses that causes fogging.

So your lenses and vision stay clear when you make the transition from a cold environment to a warm one. It may also keep your lenses from fogging up during sports and other times you are hot and perspiring.

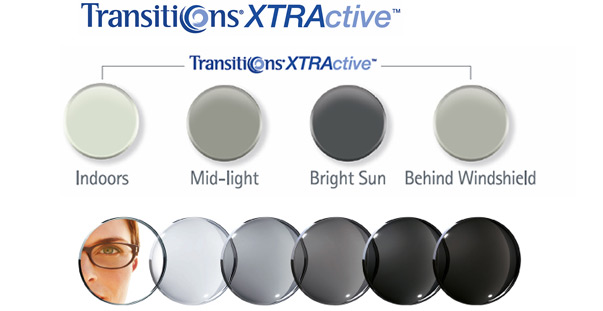

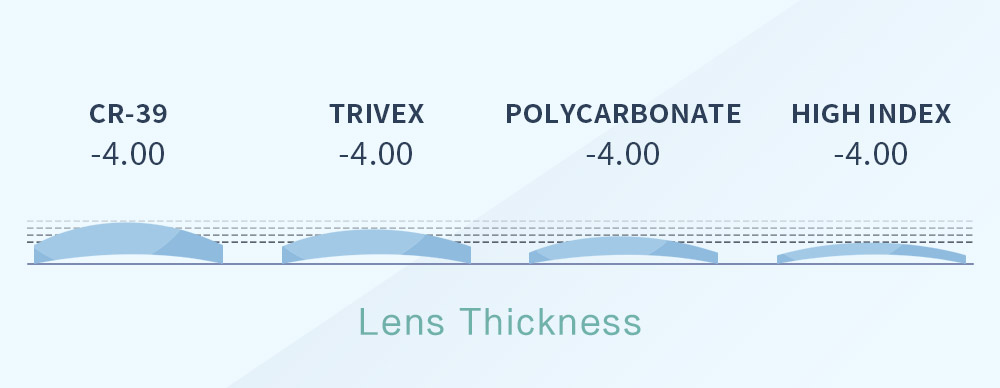

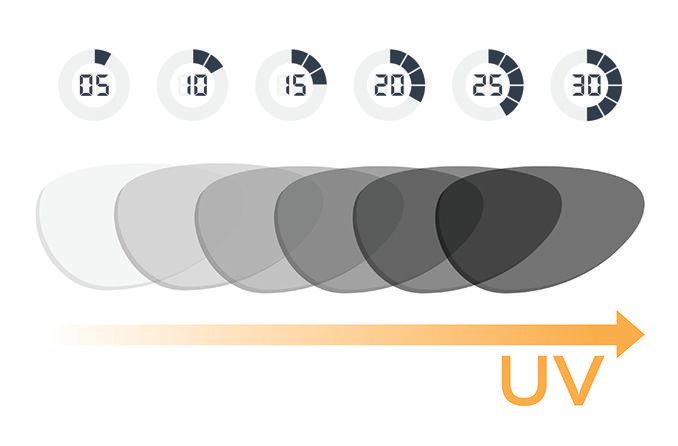

Fog Free can be applied to plastic, polycarbonate and other eyeglass lenses, including high-index lenses and Transitions photochromic lenses. The anti-fog coating is applied to the lenses before they are cut to fit into your frame at the optical lab. Ask your optical retailer about pricing and availability.

Fire ants can cluster together to increase their buoyancy – a property that scientists hope to copy to clean up oil spills -- superomniphobic surfaces

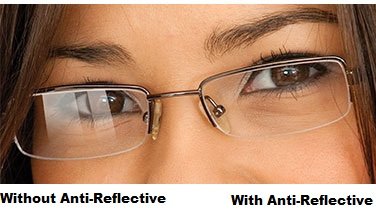

In October 2011, Essilor introduced a line of eyeglass lenses called Optifog, which the company describes as "a breakthrough lens with an exclusive anti-fog property."

The anti-fogging property of Optifog lenses is activated by applying a drop of Optifog Activator to each side of the lens, then wiping the lens with a microfiber cloth to thoroughly spread the liquid across the entire lens surface. This treatment keeps the lenses fog-free for up to one week, according to Essilor.

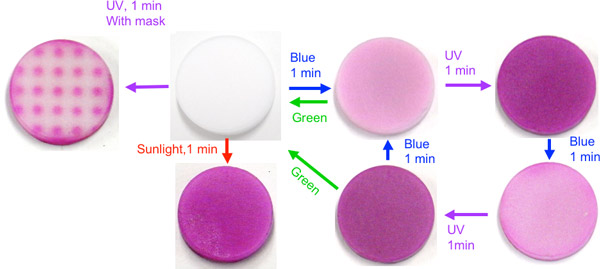

Lens fogging is caused by tiny water droplets that form by condensation on the surface of eyeglass lenses when the lenses are significantly cooler than the surrounding air temperature. Optifog works by uniformly spreading these water droplets across the lens surface so they become invisible, Essilor says.

What is hydrophobic cloth? [6]

Hydrophobic nonwovens are used for products that are intended to provide a dry barrier, while withstanding moisture. Some fibers, such as polyester, naturally have hydrophobic characteristics. In other cases, coatings and treatments can be used to make hydrophobic material from naturally absorbent fiber like cotton.

What is an example of a hydrophobic material? [7]

Hydrophobic molecules are molecules that do not have a charge, meaning they're nonpolar. Hydrophobic materials often do not dissolve in water or in any solution that contains a largely aqueous (watery) environment.

Oil, waxes, and steroids are all examples of hydrophobic materials and molecules.

Optifog lenses are available in plastic, polycarbonate and high-index plastic lens materials, with or without Essilor's proprietary Crizal anti-reflective coating.[3]

Reference:

- en.wikipedia.org/wiki/Hydrophobe

- encyclopedia2.thefreedictionary.com/Hydrophobic+Coatings

- allaboutvision.com/lenses/coatings.htm

- sciencedirect.com/science/article/abs/pii/S0927775721018422

- chemistryworld.com/features/superhydrophobic-materials-from-nature/3010321.article

- wptnonwovens.com/blog/hydrophobic-material-vs-hydrophilic

- study.com/learn/lesson/hydrophobic-effect-molecules-examples.html

- clearlyfiltered.com/articles/is-water-wet

وبلاگ تخصصی عینک شامل مجموعه مطالب پزشکی است که اطلاعات مفیدی در رابطه با عینک , چشم، لنز، سلامتی چشم و راه های پیشگیری از بیماریهای چشمی، کنترل و درمان آن را در اختیار شما کاربر محترم می گزارد.

وبلاگ تخصصی عینک شامل مجموعه مطالب پزشکی است که اطلاعات مفیدی در رابطه با عینک , چشم، لنز، سلامتی چشم و راه های پیشگیری از بیماریهای چشمی، کنترل و درمان آن را در اختیار شما کاربر محترم می گزارد.